Demand planning and forecasting: How Machine Learning can help

Demand planning is the process of forecasting future demand for a product or service. It involves analyzing historical sales data, market trends, and other factors to predict how much of a particular item will be needed in the future. The goal of demand planning is to ensure that a company has the right amount of inventory on hand to meet customer demand, while minimizing the cost of carrying excess inventory.

How is demand planning done in CPG?

The most advanced consumer packaged goods (CPG) companies gather tons of data from their managers and the market. For example, sales or business development departments would provide information about sales fundamentals while brand marketing would provide brand health measurements. Below are a few examples of these other factors that can be considered:

- Distribution uplifts on a per SKU basis by region or even account level

- Promotions calendar covering not only timing but also depth of discount, frequency of promotions, promo communication, and others

- Shelving space by actual inches or cm and also by share as compared vs competitors

- Display space by actual count and also share as compared vs competitors

- Reach and frequency of advertisements

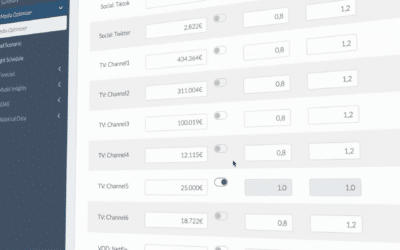

- Investment in different media channels

Product supply department would then take these inputs and analyze it together with market data with mostly historical information mixed in with some market insights from the consumer market department. Once the demand planning has produced the forecasts, both finance and product supply departments will adjust their financing and inventory orders. However, if either of the top management, marketing, or sales are unhappy with the results of the forecast, the entire process needs to be redone until all departments are in agreement.

Why is demand planning important and which CPG functions participate?

This process can take months and should be done at least 9 months ahead of execution. Truth be told that a lot of managers dread this process. However, this demand planning exercise is a make or break activity for brands that want to compete in the market responsibly and without risking the entire company.

Is finance affected?

Demand planning helps identify the right level of financing needed. Does the company need to borrow more in order to finance its marketing efforts? Or can the company afford its marketing levels thanks to expected revenues from the fiscal year ahead?

Should sales care?

This activity also aligns sales with the company priorities and go-to-market plans. What are the brands and products to focus on? What activities can and should I do to push these priorities? Which accounts do we activate in order to deliver the expected revenues?

Is demand planning in the supply chain?

Demand planning very much helps the product supply department. The numbers help guide them how much to order and time the deliveries and receiving. They will also know if they have enough warehouses to store inventory or if they need ad hoc warehousing. Product supply will also have an idea if they are currently experiencing a bullwhip effect or not.

Do marketers benefit?

Of course, demand planning brings everything together and helps marketers streamline all their efforts. Are they highlighting the correct brand or product in their campaigns? Will the product be available in-store once the consumers are interested? Will the product not run out before the campaign ends? Will the brand achieve its market share and revenue objectives?

Effective demand planning is critical for businesses to ensure that they have the right products in stock at the right time. It can help minimize stock outs and overstocks, reduce inventory carrying costs, and improve customer satisfaction by ensuring that products are available when customers want them.

How is demand planning currently done?

There are several methods of demand planning, and the choice of method depends on the nature of the business, the product or service being offered, and the availability of data. Here are some of the most commonly used methods:

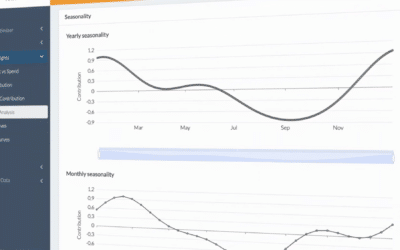

- Statistical forecasting: This involves using historical sales data to identify patterns and trends, and then using this information to predict future demand. This method can be further broken down into various sub-methods such as time-series analysis, regression analysis, and exponential smoothing.

- Market research: This method involves gathering data on customer preferences, buying habits, and other relevant factors that may affect demand. This information is then used to create a demand forecast.

- Collaborative planning, forecasting, and replenishment (CPFR): This method involves sharing demand data between a company and its suppliers, distributors, and other partners to improve demand planning accuracy. This method relies heavily on data sharing, collaboration, and communication.

- Expert opinion: This method involves gathering input from industry experts, internal stakeholders, and other knowledgeable sources to identify potential changes in the market that could impact demand.

- Simulation models: This method involves creating models that simulate various demand scenarios and their outcomes. This method can help companies plan for unexpected changes and uncertainties.

Each of these methods has its advantages and disadvantages, and the choice of method depends on several factors, including the size and complexity of the business, the availability and quality of data, and the level of accuracy required for demand forecasting.

What are the limitations of the current practices?

Despite the many benefits of demand planning, there are several limitations to current practices. Here are some of the most significant ones:

- Lack of cross-functional collaboration: Demand planning requires input and collaboration from multiple departments, including sales, marketing, operations, and finance. However, many companies struggle to facilitate effective communication and collaboration between these departments, leading to silos and inconsistent data.

- Inflexibility: Traditional demand planning methods can be inflexible and slow to adapt to changing market conditions. This can make it difficult for companies to respond quickly to changes in demand and may result in overstocking or stockouts.

- Lack of scalability: Many traditional demand planning methods are not easily scalable, making it difficult for companies to adjust their forecasting methods as their business grows or their product mix changes.

- Inability to account for new products or trends: Demand planning methods are typically based on historical data, which may not be useful in predicting demand for new products or emerging trends. This can make it difficult for companies to accurately forecast demand for these items.

These limitations suggest that demand planning practices need to evolve to become more agile, adaptable, and responsive to changes in the market. Companies need to embrace new technologies and data-driven approaches to improve the accuracy and flexibility of demand planning. They also need to foster a culture of collaboration and cross-functional communication to ensure that all relevant departments are involved in the demand planning process.

How can demand planning be improved?

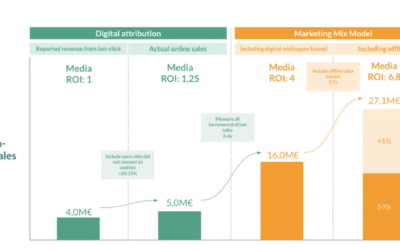

Machine learning (ML) has significantly improved demand planning by helping companies analyze large amounts of data to identify patterns and predict future demand more accurately. Here are some of the ways in which ML have improved demand planning:

- Improved accuracy: ML have improved demand forecasting accuracy by analyzing large amounts of data from multiple sources, such as historical sales data, social media, and external market factors. By identifying patterns and predicting future demand more accurately, companies can avoid stock outs or overstocks, leading to higher customer satisfaction and profitability.

- Real-time data analysis: Machine Learning can analyze data in real-time, enabling companies to quickly identify changes in demand and respond accordingly. This has enabled companies to adjust their inventory levels and production schedules more effectively, reducing waste and improving efficiency.

- Scalability: Machine Learning can be easily scaled to analyze larger data sets or more complex data, making them ideal for companies with large product portfolios or complex supply chains. This has enabled companies to handle more data and generate more accurate forecasts, even as their business grows.

- Predictive modeling: Machine Learning can create predictive models that can be used to forecast demand under different scenarios or assumptions. This has helped companies better understand the impact of various factors on demand and make more informed decisions.

- Improved collaboration: Machine Learning has helped improve collaboration between different departments by providing a common language and framework for understanding the impact of marketing and other factors on sales. This has helped break down silos and foster a culture of collaboration and communication, leading to more accurate and effective demand planning.

Machine Learning has become an essential tool in demand planning to help companies generate more accurate forecasts, allocate resources more efficiently, and optimize marketing and sales strategies. By leveraging the power of data and statistical analysis, companies can improve their supply chain efficiency, customer satisfaction, and profitability.

Contact Indaru and learn more about demand planning!

Follow us on Linkedin

Image by a href on Freepik